Freight operations involving hazardous materials and complex multi-leg routes demand precision, compliance, and seamless coordination. These shipments often require special handling, strict documentation, and collaboration between multiple carriers and regulatory bodies.

Businesses must rely on advanced systems and experienced partners to support hazardous goods and multi-leg routes with ease, ensuring that every stage of transport runs safely and efficiently. Professionals such asmatthew marshall have highlighted how modern logistics platforms make it possible to manage risk, maintain compliance, and simplify operations through automation and real-time visibility.

Understanding Hazardous Goods Transport

Transporting hazardous materials requires careful planning and adherence to legal standards that protect people, property, and the environment.

What Defines Hazardous Goods

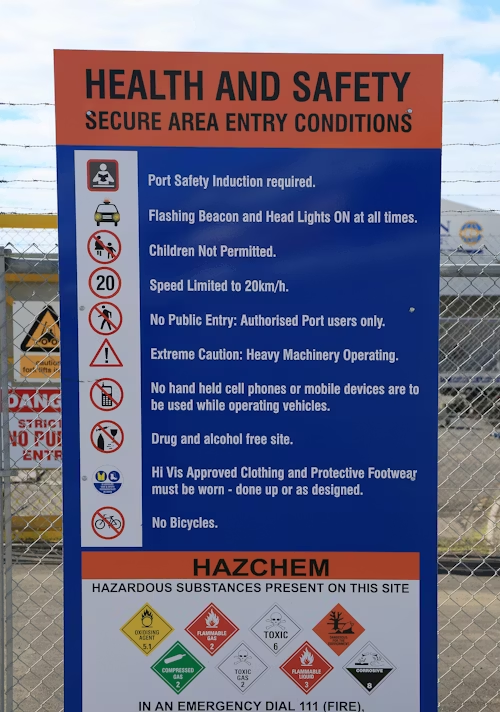

Hazardous goods include items that pose risks due to their chemical, physical, or biological properties. These can range from flammable liquids and corrosive substances to pressurised gases and radioactive materials. To handle such freight safely, companies must follow national and international regulations governing packaging, labelling, storage, and transit.

Compliance and Responsibility

Compliance in hazardous goods transport is non-negotiable. Businesses must ensure that documentation, labelling, and carrier certifications meet all required standards. Non-compliance can lead to legal consequences, safety hazards, and reputational damage.

Using systems that support hazardous goods and multi-leg routes with ease ensures all relevant details are managed consistently across every shipment and region.

The Complexity of Multi-Leg Freight Routes

Multi-leg routes add layers of complexity to freight operations, especially when they involve hazardous goods.

Managing Multiple Transport Modes

Shipments that move across road, rail, air, and sea require coordination between several carriers. Each mode may have its own regulations and safety requirements. Managing documentation, transfer points, and timing across these transitions requires precision and visibility that only integrated systems can provide.

Coordinating Global Supply Chains

International shipments increase complexity further through customs procedures, time zone differences, and varying safety standards. Businesses using platforms designed to support hazardous goods and multi-leg routes with ease benefit from centralised communication and automated compliance features that ensure seamless global operations.

Technology Enabling Safer Freight Operations

Technology plays a key role in ensuring compliance and efficiency when handling hazardous materials and multi-leg routes.

Centralised Freight Management

Integrated logistics platforms centralise all shipment details, from route planning and carrier assignment to documentation and compliance tracking. This visibility allows logistics teams to manage multiple legs of transport simultaneously, reducing the chance of missed updates or lost paperwork.

Automation for Efficiency

Automation eliminates manual processes that often cause delays and errors. Systems automatically generate transport documents, verify safety requirements, and update stakeholders in real time. This ensures that businesses can support hazardous goods and multi-leg routes with ease while minimising administrative workload.

Ensuring Safety in Hazardous Goods Transport

Safety remains the top priority when transporting hazardous freight. Technology and training work hand in hand to protect personnel and assets.

Real-Time Monitoring and Alerts

Modern logistics systems use sensors and tracking devices to monitor conditions such as temperature, vibration, or pressure. Any deviation from safe thresholds triggers instant alerts, allowing operators to take immediate action. This visibility ensures goods remain stable and compliant throughout transit.

Training and Certification

Drivers and logistics personnel handling hazardous freight must undergo specialised training. They need to understand classification systems, packaging standards, and emergency procedures. Digital platforms can store certification records, ensuring that only qualified individuals manage dangerous shipments.

Optimising Multi-Leg Route Planning

Complex routing requires careful coordination and access to accurate data.

Route Optimisation for Efficiency

Automated route planning tools assess variables such as distance, regulations, and delivery windows to determine the most efficient path. When multiple carriers and regions are involved, these tools create optimised routes that reduce transit times and costs. Businesses can support hazardous goods and multi-leg routes with ease by using data-driven algorithms that prevent unnecessary delays.

Managing Interchange Points

Transfer points between modes or carriers represent high-risk areas for delays or errors. Technology ensures that all parties receive synchronised information, reducing miscommunication. Automated notifications confirm handovers and prevent missed connections during complex journeys.

Compliance Through Integrated Systems

Compliance tracking is a fundamental part of safe logistics operations. Integrated software makes it easier to maintain compliance across multiple jurisdictions.

Automated Documentation and Labelling

Systems automatically generate shipping labels, safety data sheets, and manifests that comply with relevant standards. By maintaining consistency across shipments, automation reduces the risk of missing or incorrect documentation.

Streamlining Regulatory Reporting

When companies operate internationally, they must comply with multiple reporting requirements. Integrated platforms allow data to be exported directly into regulatory formats, simplifying audits and inspections. This efficiency supports the broader goal to support hazardous goods and multi-leg routes with ease without compromising accuracy.

Collaboration Between Stakeholders

Effective hazardous goods transport relies on cooperation between suppliers, carriers, and regulatory agencies.

Real-Time Communication

Centralised platforms allow all stakeholders to communicate through one interface. Updates on shipment status, compliance checks, and incident reports are instantly shared, reducing response times and improving transparency.

Strengthening Partner Relationships

By maintaining consistent communication and clear expectations, businesses build stronger partnerships with carriers and authorities. Trust and accountability become key assets in maintaining safe and reliable operations.

Managing Risk in Hazardous Freight

Risk management ensures that potential issues are identified and mitigated before they affect delivery performance.

Proactive Risk Assessment

Integrated freight systems assess routes, carriers, and cargo types to predict risks such as regulatory restrictions or adverse weather. Real-time data allows planners to make informed adjustments, maintaining continuity even during disruptions.

Contingency Planning

Unexpected delays or incidents require swift action. Systems that support hazardous goods and multi-leg routes with ease include automated contingency planning, redirecting shipments or activating backup carriers when necessary. This flexibility keeps supply chains moving safely and efficiently.

Improving Visibility Across Multi-Leg Shipments

Visibility across all legs of transport is essential for managing performance and maintaining control.

End-to-End Tracking

Advanced tracking technology offers a complete view of the shipment’s journey, from origin to destination. Each transition between carriers is recorded, ensuring that goods are traceable at every step.

Performance Analytics

Data collected from shipments helps assess performance metrics such as delivery times, compliance incidents, and handling quality. This visibility supports continuous improvement and helps companies refine future operations.

Reducing Costs Through Automation and Efficiency

Automation and digital connectivity not only improve safety and compliance but also reduce operational expenses.

Minimising Manual Workload

Automated documentation, billing, and scheduling reduce the number of labour hours spent on administrative tasks. These efficiencies translate into lower operational costs and faster turnaround times.

Preventing Fines and Delays

Compliance failures or inaccurate paperwork often result in fines and shipment delays. Automated systems minimise these risks by ensuring that every shipment meets legal and regulatory requirements before departure.

Sustainability and Responsible Freight Management

Sustainability has become a core focus in logistics, particularly when transporting hazardous materials.

Reducing Environmental Impact

Optimised routing and efficient scheduling reduce fuel consumption and emissions. Digital documentation eliminates paper waste, contributing to sustainable logistics practices.

Ensuring Safe Disposal and Recycling

Hazardous materials require careful disposal or recycling. Integrated systems track materials through their entire lifecycle, ensuring that disposal complies with environmental standards. By integrating sustainability, companies can support hazardous goods and multi-leg routes with ease while maintaining corporate responsibility.

The Future of Hazardous Goods Transport

The future of logistics will be shaped by automation, artificial intelligence, and greater interconnectivity between systems.

Artificial Intelligence and Predictive Analytics

AI-driven systems can predict maintenance needs, compliance risks, and potential delays before they occur. Predictive analytics allows logistics teams to act early, preventing accidents and improving service reliability.

Expanding Connectivity Across Networks

As logistics networks become more connected, data sharing between carriers, ports, and regulators will improve visibility and traceability. This interconnected ecosystem will make it easier for businesses to manage hazardous freight safely on global scales.

Frequently Asked Questions

How does technology improve hazardous goods transport?

Technology automates compliance checks, monitors shipments in real time, and manages documentation. These features reduce risk, improve safety, and ensure accurate reporting across every stage of the journey.

Why is managing multi-leg routes challenging?

Multi-leg routes involve multiple carriers, modes, and transfer points. Each stage has unique regulations and timeframes. Centralised systems streamline coordination and prevent delays through automation and real-time visibility.

Can automation reduce compliance errors?

Yes. Automation ensures that documentation, labelling, and reporting follow standard formats. It eliminates manual entry errors and automatically updates regulatory information across all shipments.

Conclusion

The ability to support hazardous goods and multi-leg routes with ease defines the success of modern logistics operations. Through automation, integration, and centralised visibility, businesses can manage complex freight movements safely and efficiently. Advanced technology ensures compliance, reduces administrative workload, and enhances communication between all stakeholders.

As global supply chains continue to expand, systems designed for scalability, safety, and precision will become essential. By combining human expertise with digital innovation, companies can move hazardous goods with confidence, maintain regulatory integrity, and ensure seamless transport across every leg of the journey.